What is lathe machine? A Lathe Machine also known as Turning Machine which operates by rotating a workpiece about its axis to perform various machining operations such as cutting, drilling, reaming, tapping, parting, facing, threading, knurling and perform other operations. A single point cutting tool is fed against the rotated workpiece to remove the excess material or unwanted material to form a cylindrical shaped product. With a proper attachments and adjustments, a lathe can also bore, polish and grind. The variety of operations that lathe can perform make it one of the most useful and necessary machines in the market

Lathe Single Point Cutting Tool

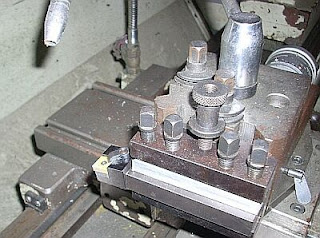

Lathe Cutting Tool Carriage

The lathe operates on the principle of the work being rotated against the edge of a cutting tool. The major function of the lathe machine is to change the size and shape of a rotated workpiece by one cuts or a series of cuts with cutting tools that can be adjusted to the workpiece. The cutting tool is controllable and can be moved lengthwise on the lathe bed and into any desired angle across the rotated workpiece.

Manual turning machine also known as a conventional lathe machine or turning machine and the cutting operation is partially control mechanically or can be fully controlled manually which is designed to produce parts within an accuracy range of 0.01 mm. The ultra-precision turning machine is known as CNC Turning Machine. It has high levels of accuracy and repeatability which operates in micron ranges and this machine has a dimensional accuracy ten times better than a conventional lathe.

Manual Turning Machine

Precision CNC Turning Machine

Photos by Republic Lagun Machine Tool

Lathe Machine

Label: Lathe Machine